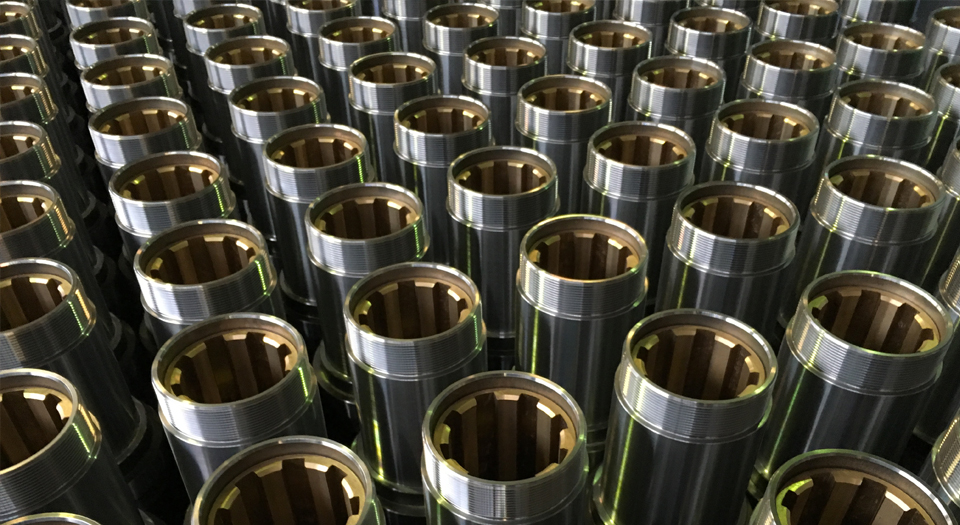

Application Types

Bebi Meccanica is capable of supplying products and services both to plant and machinery manufacturers and to original equipment manufacturers (OEM) offering:

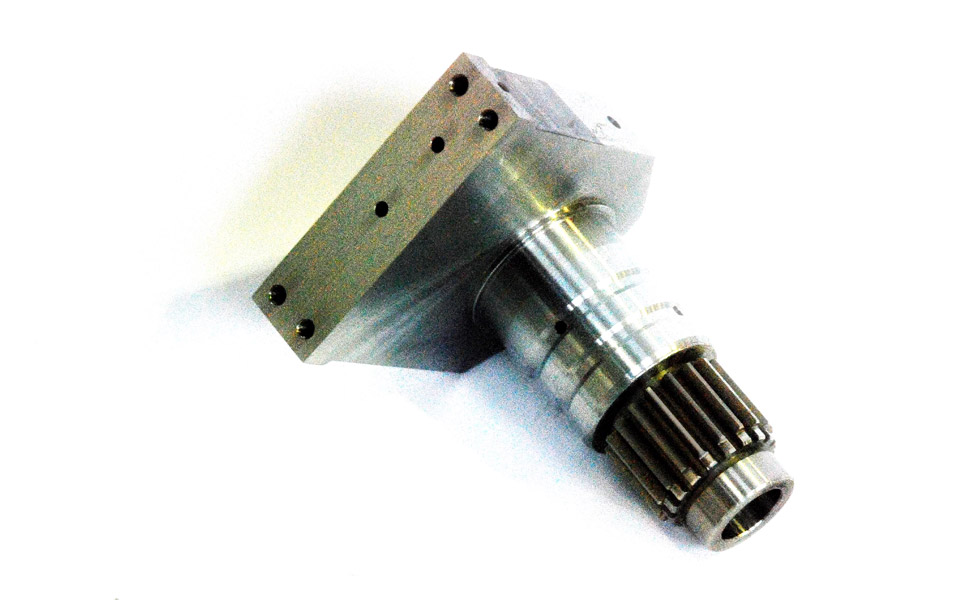

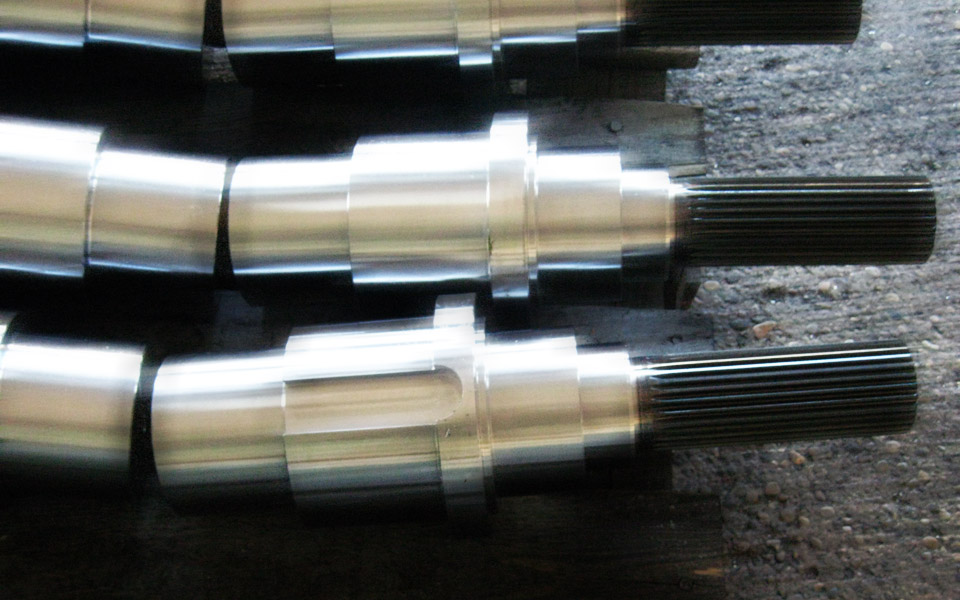

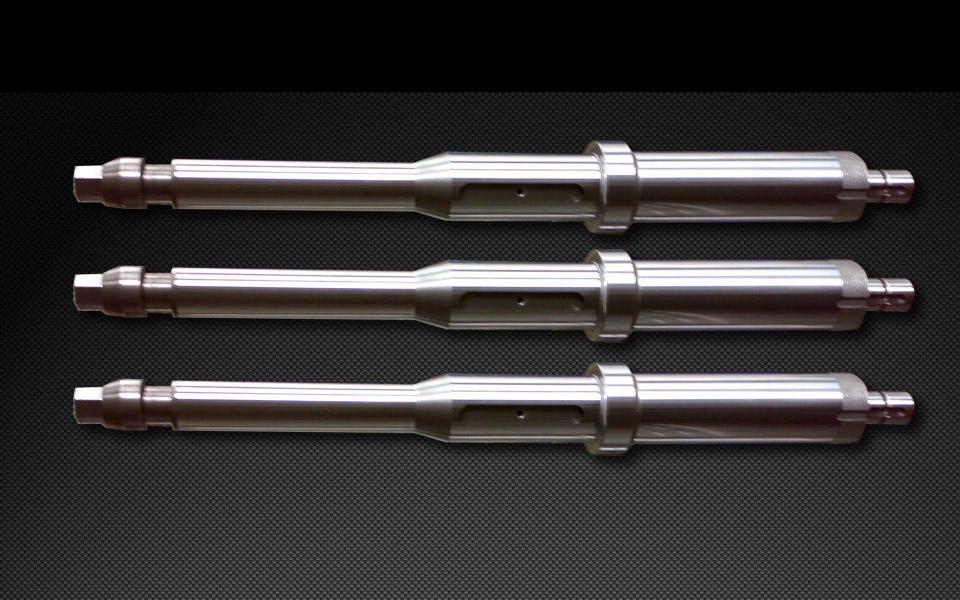

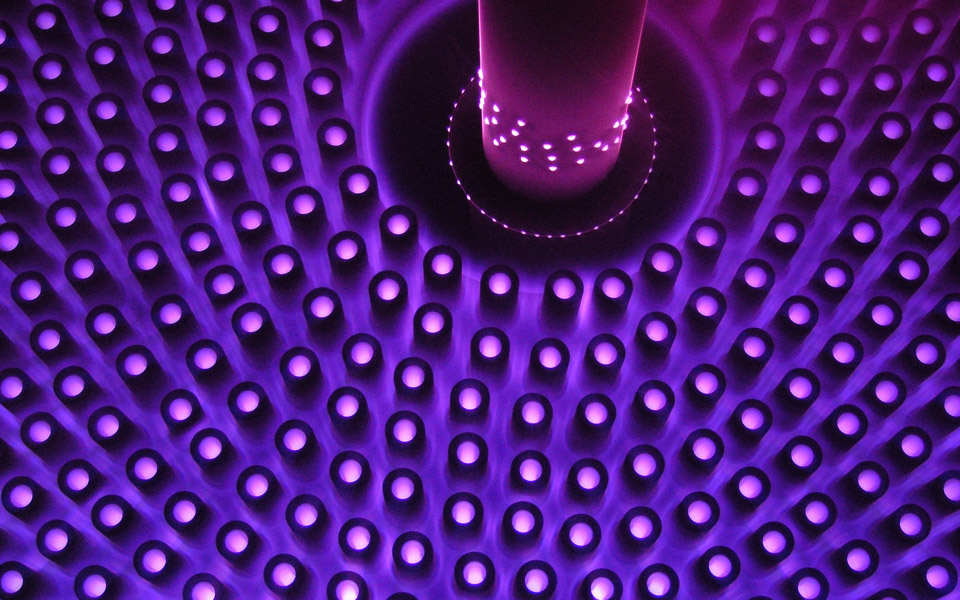

- technologically advanced and complex products

- complete machining, simplifying the entire purchasing process of the whole supply chain for the customer

- integrated services and technical support in all phases of the production process

- significant logistic advantages favoured by the reduction of delivery times within the entire supply chain by customising management of the final warehouse of the customer and of shipping.